Record: every touch ... of every Process ... for every Product

Do you need to keep records of your processes?

What would you do with a solution that can Automatically collect and manage every detail about the processes your product has encountered?

- Quality

- Process Conditions

- Test / Calibration Results

- Material, Sub Assemblies

- Timings, Activities, etc.

KwikTic Traceability offers you all of this for both Automated (Industry 4.0 / Smart Factory) and Manual processes.

Trace what you need with more accuracy and less effort.

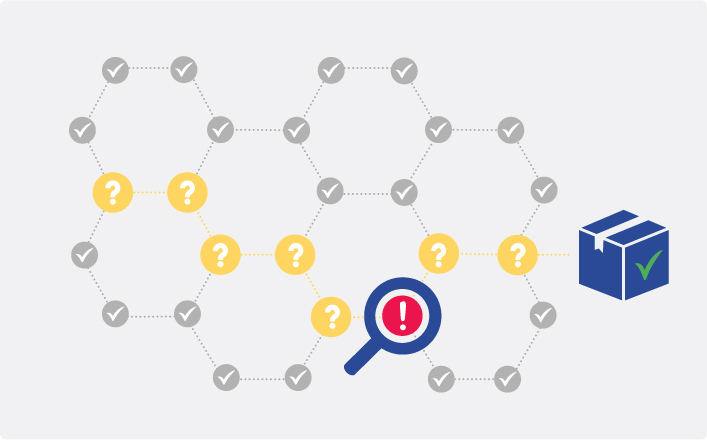

Quickly find all components related to an assembly or built under certain conditions.

Compliance

Keep records with ease.

Satisfy the standards you need to achieve with confidence.

Every Touch

Every time a product is processed, whether it is automatic by a machine or manual by an operator, all details are recorded.

Material

Materials can be traced from Goods In through to which products they were used on.

Easily find all products which used material form the same batch / reel / box / etc.

Quality

All aspects of Quality can be recorded and Serial Number, providing evidence that the product was manufactured in specification and that any repairs / corrections or calibrations were performed correctly

- Details of any quality issues

- Test and Calibration results

- Repairs (if any)

- Process conditions

- Material used

- Tools used

Serial Number or Batch

KwikTic can trace down to individual Serial Number level. But not all products can have Serial Numbers, so it is also possible to record to a Batch level, or even a mix of both.