Never miss a step + Live WIP tracking

Increase your process control and ensure your product stays on the right path. With KwikTic enforced routing, you decide the route and KwikTic will keep them headed in the right direction.

KwikTic can ensure all processes are completed successfully for each product.

Each product has its own route and can also have alternate routes to cope with available resources. (E.G. If a line is down, there may be an alternative way to process a product).

Each step in the Process Route is tracked and data captured for that manufacturing process. The data may be as simple as Date, Time, User, Station and Serial Number or Batch. But it could also include Test Results, Defects found, process conditions, etc.

KwikTic will control who can / cannot complete a process. It will also present the correct information to the user saving time and reducing the chance of error.

BOOST YOUR PRODUCTIVITY

- Eliminate Errors and improve quality – Right 1st Time.

- Never miss a Test, Inspection or any other process.

- Fully record all actions. (Track and Trace).

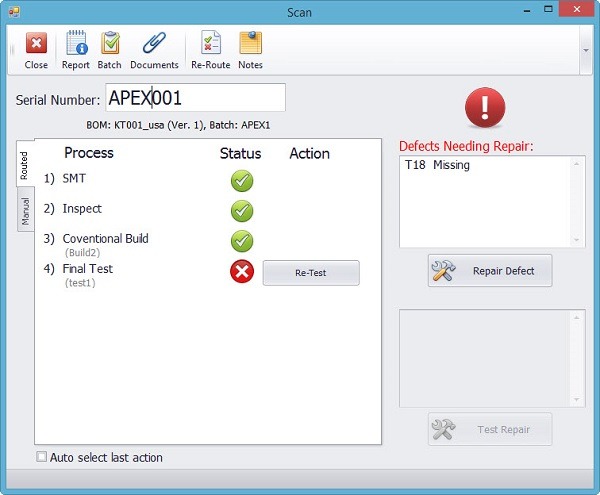

- Identify outstanding issues (Open Repairs or Test Failures).

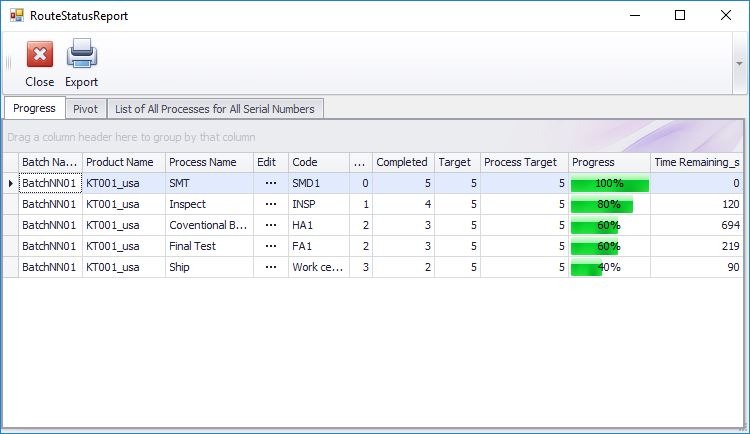

- Track Progress and Monitor efficiency.

- Less shopfloor decisions.

- Time real time operations.

FEATURES

- Set user rights to ensure only authorised personnel perform the correct activities.

- Record every touch, not just user name, time stamp, work location, every step complete, test result, defect found, repair, etc.

- Prevent leap frogging to an incorrect step.

- Automatically select the required Work Instruction.

- Live visibility of production progress.

- Create route in minutes within the KwikTic, or synchronise with your MRP / ERP.

- Clearly show when repairs are required.

- Works with Manual Scanning, Auto In-Line Scanners and Direct communication to Machines (Industry 4.0).

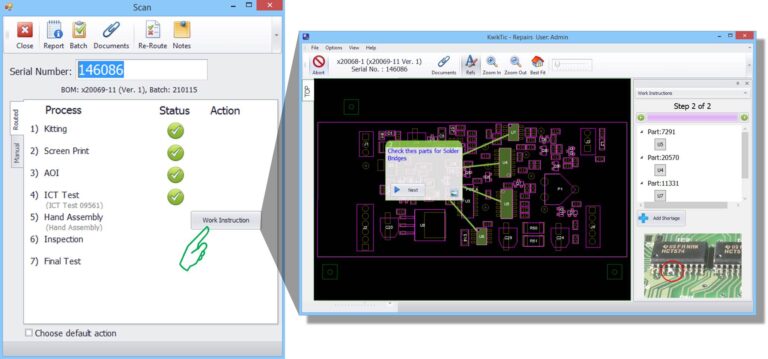

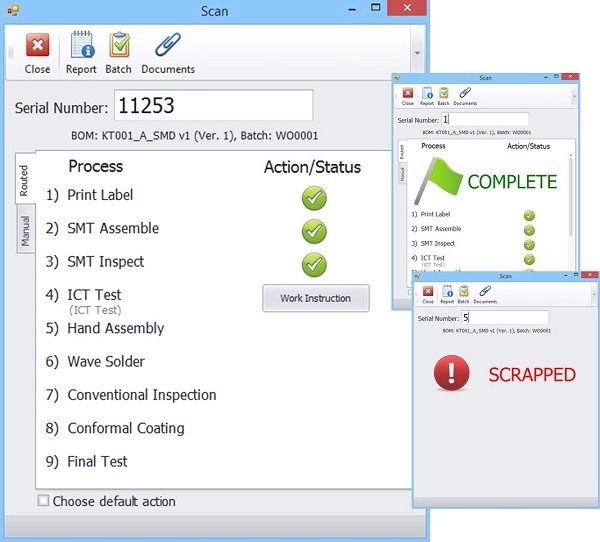

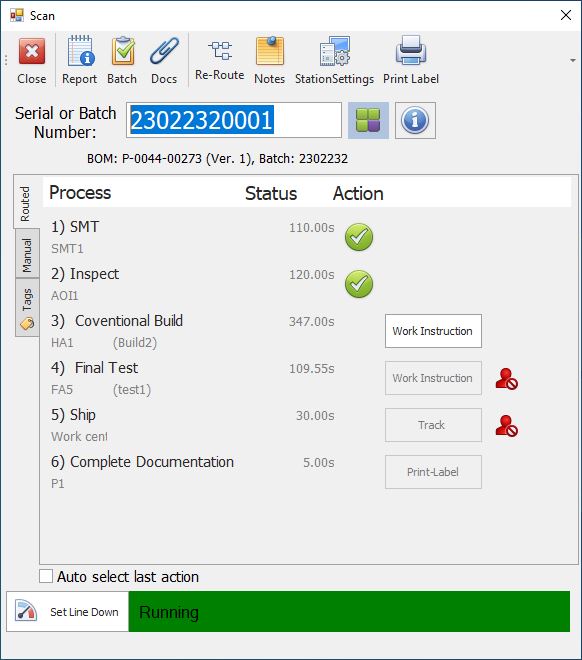

Scanning a Serial Number shows the completed and remaining processes needed to complete the product.

Each step of the Route is shown for the Serial Number. Of the process is complete, then the green Tick indicated complete and no further action necessary.

In the image, we ca see that the first 2 steps (SMT and Inspection) have been completed.

The Next process step is “Conventional Assembly” (Note. You can name each step to suit your own terminology when you set up Product Routes). This Conventional Assembly process requires the operator to follow a Work Instruction (called “Build2”), so the button marked “Work Instruction” will automatically select the correct Work Instruction for this process, saving time and ensuring the correct instruction is opened for the operator. Also, the Work Instruction will use the correct BOM, showing the relevant part numbers for this version of Product.

The following 3 steps are not yet enabled as they need to be completed in turn. KwikTic also has the flexibility to enable certain process steps to be actioned out of sequence if required.

In addition to the the steps not being enabled due to sequence reasons, the current User does not have permissions to perform “FA5” or “Work cent” (for “Final Test” and “Ship” processes). Therefore, this particular user would be restricted from performing these processes and they could only be completed by a Trained user at an applicable Station. Again, preventing errors.

No Serial Numbers - no problem

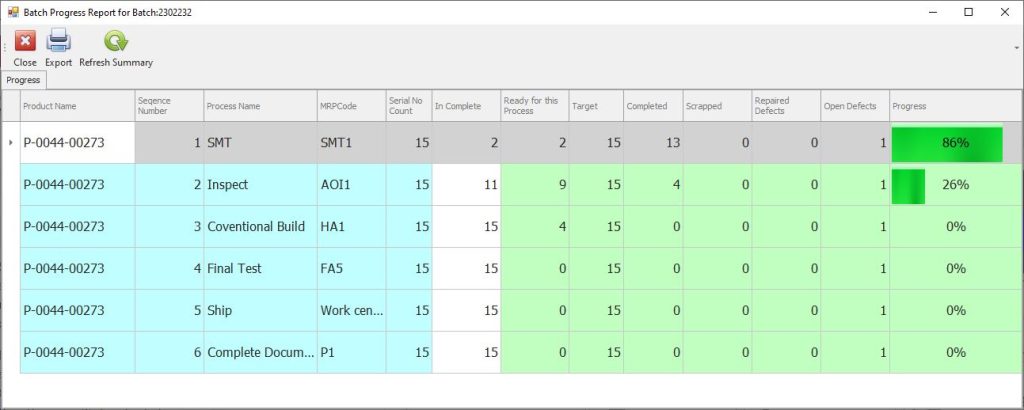

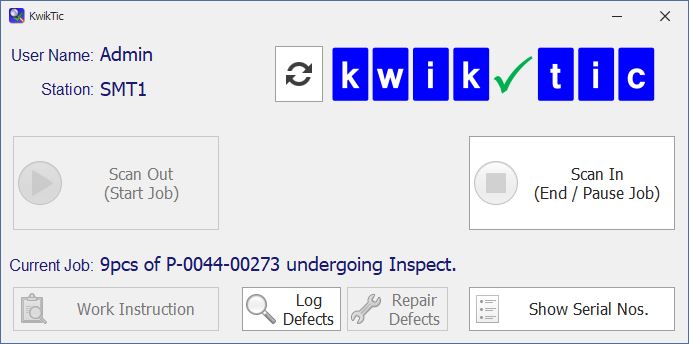

If no Serial Numbers are available, KwikTic still has options to track production Batches based purely on quantity of products processed.

A single station can be used by multiple users to start or end the process they are completing.

Times taken are recorded along with the rest of the process information.

If any of the products are found to have a defect, then a single Serial Number label can be printed for the specific products, meaning their repair can be tracked or if it is a repeat offending product, the number of faults can be tracked.

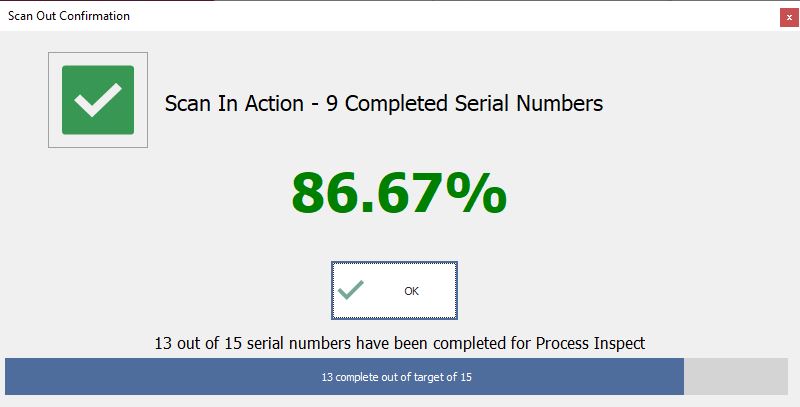

On completion, a progress screen is shown showing the percentage complete.

The scan In/Out features can be used along side the individual Serial Number scanning.

The progress of Batches / Work Orders can be seen live using the Batch Progress dashboard.