Simple Steps to Better Quality

Simplifying Work Instructions with KwikTic

Work Instructions in manufacturing can take many forms, from printed manuals to digital PDFs or even verbal training. While each method has its strengths, traditional approaches often lack flexibility, accessibility, and real-time control. This is where KwikTic revolutionizes Work Instructions, making them more usable, adaptable, and centrally managed for a seamless manufacturing process.

KwikTic Work Instructions are a great way to reduce build time and improve quality by putting the right people, on the right tasks at the right time.

KwikTic guides and trains your operators reducing build time, improving yield and eliminating rework.

By going digital with KwikTic, you’ll eliminate cumbersome paper processes, ensure everyone always has current information, improve quality, reduce operator skill set required and much more…

Are you ready to simplify and standardize your documentation?

Also use them to collect test results, material used, process conditions.

- Simple & Faster to Create

- Instantly released to all areas

- Break down each step

- Easier for operators to use

- Interactive

- Links to other Media (Reference Images, Videos, PDFs, etc.)

- Create once and apply to all variants (Reflect BOM differences)

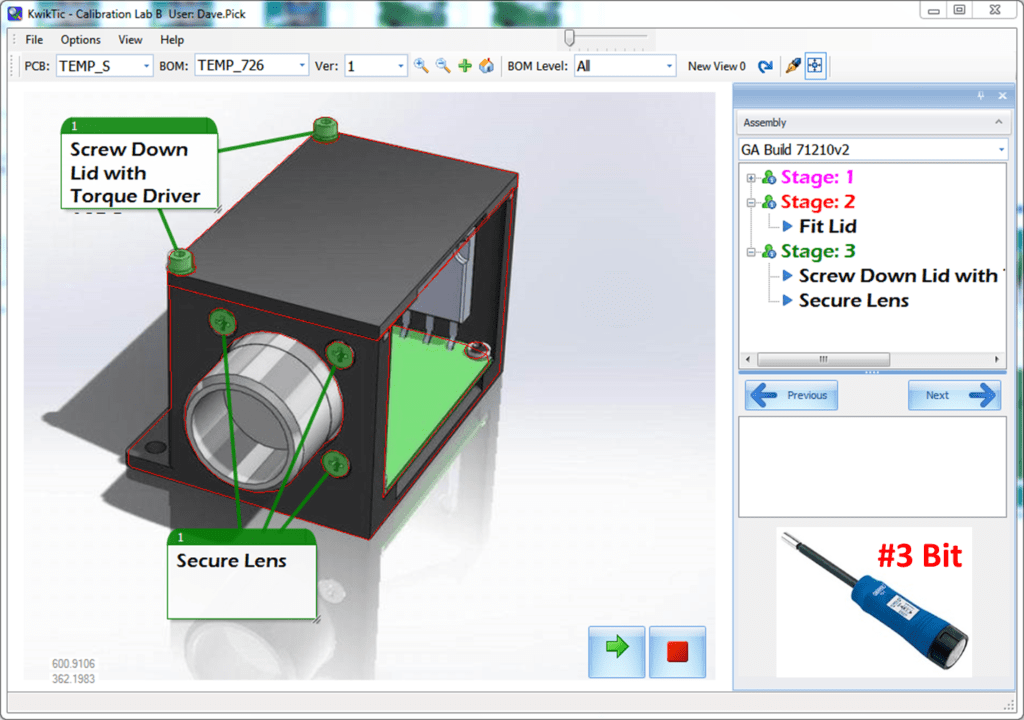

Breaking Down Steps for Better Usability

One of the challenges with traditional Work Instructions is that they can be overwhelming or unclear. KwikTic improves usability by breaking down each process into bite-sized steps, ensuring that workers can follow instructions effortlessly. Whether a task requires a simple action or detailed guidance, KwikTic accommodates all levels of complexity.

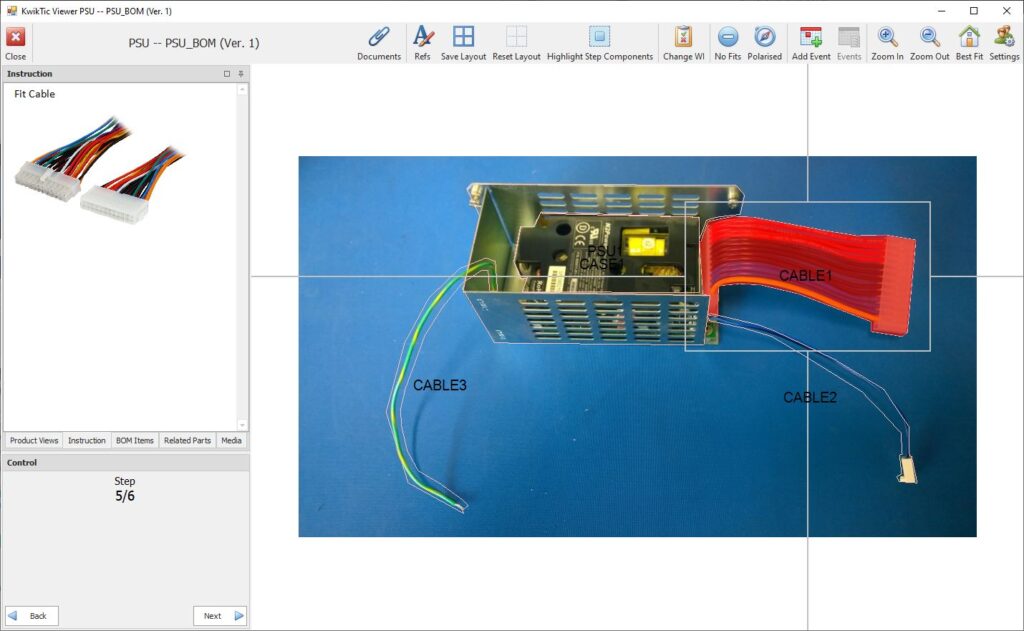

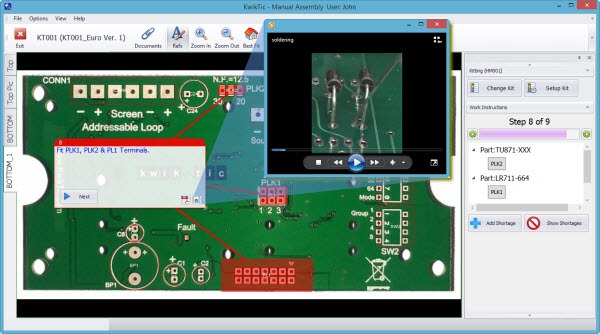

Embedding Images, Documents & Videos for Clarity

Instructions shouldn’t just be text-heavy; the more visual, the better. KwikTic enables manufacturers to embed images, documents, and videos directly into Work Instructions, providing extra clarity at crucial points. Whether it’s a diagram, safety checklist, or instructional video, employees have access to the most relevant and up-to-date materials for each step.

Centralized Control for Accuracy & Instant Delivery

One of the biggest risks in manufacturing is outdated instructions circulating on the shop floor, leading to inconsistencies and errors. KwikTic ensures everyone is working from the correct controlled document, eliminating the possibility of outdated materials being used. Because it’s centrally managed, updated instructions are instantly delivered to the workforce, ensuring no delays and no risk of using incorrect versions.

FLEXIBLE & EFFECTIVE

KwikTic is a digital Work Instructions solution that dramatically reduces the skill level requirement for workers in your production facility.

By building KwikTic Work Instructions into your product assembly process, your organization can optimize efficiencies, improve quality and reduce training time on new products.

SEAMLESS

Imagine a world where your staff get the exact step-by-step instructions they need, when they need them, on any device. And imagine if you could seamlessly collect data and measure the results.

SIMPLE

Create, edit and share digital work instructions in minutes. No more printed PDFs or paper, just a clear user-friendly guide that’s ready to use throughout the shopfloor.

Operators can easily find the correct revision of Instruction for the right process and access it immediately. This can be done by manually choosing the Product then the Work Instruction; Fully automatically by entering the Batch or Serial Number.

Each user can Customise their page layout to suit them.

RELIABLE, CONSISTENT & CONTROLLED

Have you ever questioned how a product should be built? How to use the machine safely and correctly? Do you want to improve your quality and cycle times? Do you want to simplify life, centralise and standardise documentation creation, distribution and revision control? With KwikTic Work Instructions you can.

Eliminate manual work instructions, paper and binders. Replace with a fully interactive electronic format. KwikTic is the tool your company needs to bring the process up-to-date and make it more effective, efficient, and safe.

Conclusion

In a fast-moving manufacturing environment, precision and efficiency matter. KwikTic transforms Work Instructions into dynamic, reliable, and easy-to-follow resources, reducing errors, improving training, and making production more agile. By ensuring step-by-step clarity, embedding helpful media, and maintaining centralized control, KwikTic delivers the future of Work Instructions—where speed, accuracy, and flexibility come together effortlessly.

- All data is stored in Central SQL Database

- Runs on basic PCs (running .NET 4.8)

- If required, interfaces with Standard Web Cams, Microscopes, Barcode Readers and Foot Pedals

- Import CAD and BOMs for detailed PCB views

- Works with Box Build and Cable assembly

Installed Up and running ready for Production Day #1